Quality Assurance for Medical Scrubs

Ensuring every garment meets the highest standards of durability, fit, and hygiene. From fabric selection to final inspection, we deliver consistent, reliable apparel for healthcare teams.

GET THE BEST

Fabric Engineering And Performance Testing

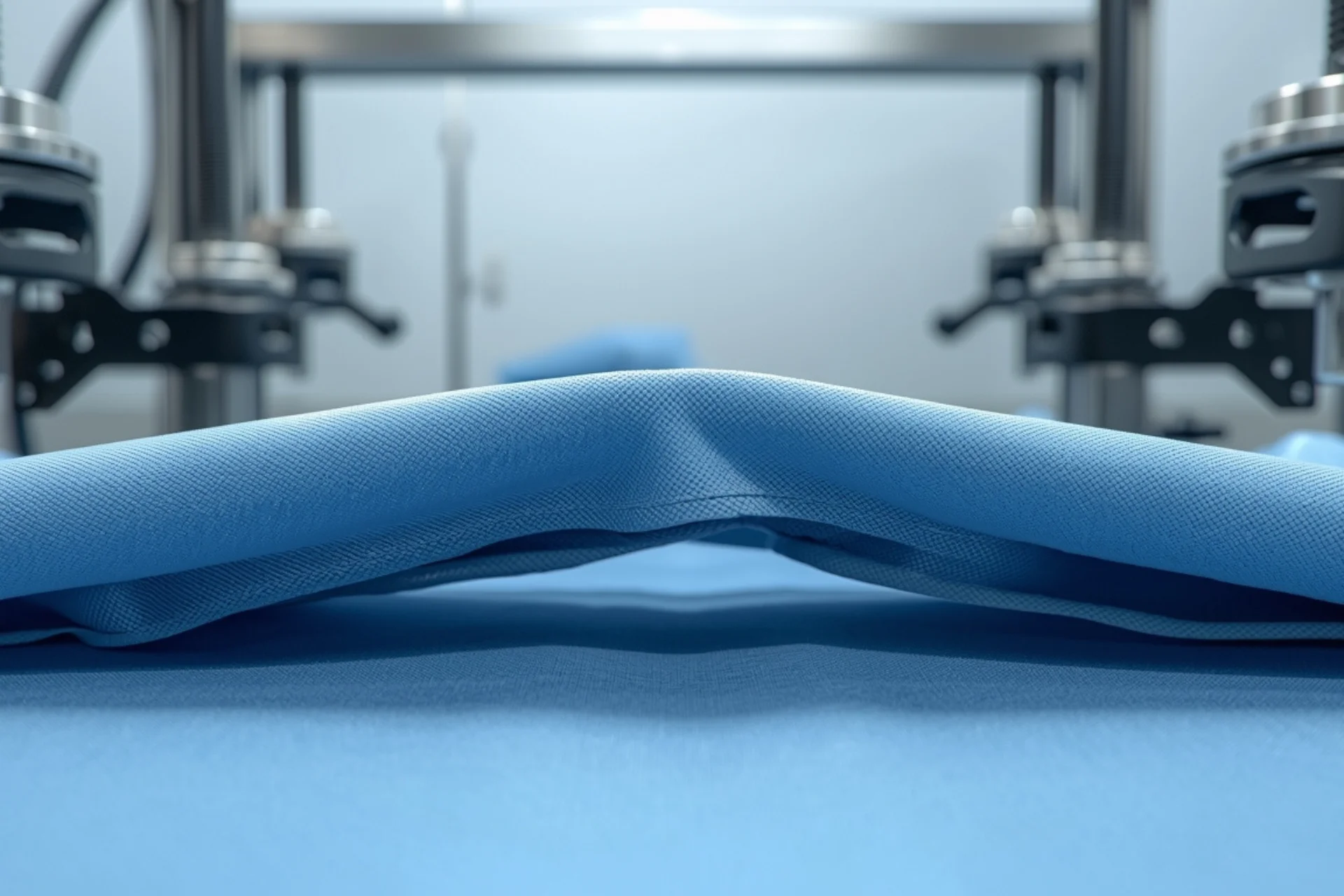

Mechanical Durability

Medical scrubs face pulling, stretching, friction, and pressure throughout every shift. Our durability tests make sure the fabric stays strong. Tensile strength tests check how well the fabric resists force, while tear resistance tests help prevent minor snags from turning into bigger damage. Abrasion tests ensure the scrubs can handle harsh surfaces, and bursting strength tests measure how much they can stretch while moving. These tests make sure the scrubs work well for long hours and repeated use.

Color Retention And Visual Consistency

Consistent color is important for team identity, department recognition, and a professional look. We test wash fastness to keep colors from fading in high-temperature washes. Tests for perspiration and rubbing resistance stop dye transfer, while light exposure tests keep the colors stable under clinical lights. These measures help healthcare teams look clean and uniform in all their garments.

Shrink Control And Dimensional Stability

Shrink control is essential to ensure clothes fit well after washing. We check wash shrinkage limits and let the fabric relax before cutting it to keep tension low. Testing for stability makes sure garments keep their shape and size over time. This helps maintain a consistent fit across production runs and prevents size changes for healthcare teams during shifts.

Comfort And Wear Performance

Comfort is key to performance during long hours in healthcare. Testing for breathability ensures airflow to prevent overheating. Moisture management keeps skin dry all day. We also evaluate how soft, flexible, and easy to move the fabric is. Optional antimicrobial treatments can be added to help keep clothes fresh and hygienic for daily use.

Quality Assurance And Fabric Sourcing

Our quality assurance program ensures that medical scrubs serve as professional healthcare wear, not just simple uniforms. We start by sourcing fabric from certified medical-grade suppliers known for quality. Each batch of fabric is tracked for bulk orders.

Before production, we inspect every roll for defects, color differences, and material quality. This process helps healthcare organizations receive scrubs that perform well, feel comfortable, and look good every time.

Garment Construction And Fit Consistency

The way scrubs are made affects how they perform during long shifts. We control seam strength and stitch density and conduct pull tests on high-stress areas to prevent seam issues. We use techniques like flat-felled seams, safety stitching, and bar tacking to reinforce important points.

All hardware, including zippers and buttons, is tested for durability and repeated use. We ensure consistent size through careful pattern grading and regular pattern checks. Golden samples and controlled cutting processes help keep sizing uniform across bulk, repeat, and custom orders.

Garment Construction Quality And Fit Control

Consistent quality is crucial for scrubs used in clinics. Workers check seam strength and stitch density during production. They add reinforcement at stress points to stop tearing. Reliable methods like flat-felled seams, safety stitching, and bar tacking strengthen important areas. Hardware parts are tested to ensure they work well even after many washes.

To ensure a good fit, workers use precise pattern grading and clear standards. They conduct regular pattern checks and create golden samples. Controlled cutting workflows help keep sizes uniform for bulk orders and custom requests for healthcare groups.

Final Inspection And Pre Shipment Validation

Every order goes through a final check to ensure it meets quality standards before shipping. Inspectors sample using AQL methods and classify defects by severity to maintain fair evaluations. They check garment sizes, labels, and packaging for accuracy, and cartons are verified to confirm order completeness. Each shipment is matched to the purchase order, and a certificate is issued to confirm it meets all requirements for delivery.

Operational Benefits For Healthcare Organizations

A straightforward quality assurance process lowers risks for healthcare organizations. Consistent quality reduces return rates, cuts down on sizing issues, and increases the lifespan of garments. This also helps control costs and reduces the workload for procurement teams. For healthcare staff, having a reliable fit and consistent look boosts confidence and supports a professional image during onboarding. This method allows uniform programs to grow while keeping consistent quality across departments and teams.

Get the best

Long Term Quality Commitment

Our quality focus is on transparent processes, open communication, and responsibility during production. We aim for the same quality in every order and partner with healthcare groups that want reliable results rather than one-time sales. This long-term approach helps create ongoing programs, steady results, and strong supply relationships as organizations expand.

Here Is Our Client's Reviews

FAQs

We control fabric lots, maintain golden samples, and monitor production settings to ensure repeat orders match approved standards in fit, color, and construction.

Fabrics are tested for durability, color retention, shrink control, and comfort to ensure they withstand repeated laundering and long clinical shifts.

Sizing is controlled through precise pattern grading, tolerance limits, fabric relaxation before cutting, and regular pattern audits across all orders.

Our processes align with OSHA guidance, CDC laundering recommendations, and hospital uniform hygiene and safety expectations.

Final inspections use AQL sampling methods, with checks for defects, measurements, labeling, packaging, and purchase order accuracy.

Early stage quality checks, consistent sizing, and durable construction help prevent common issues that lead to returns or exchanges.

Embroidery and printing are inspected for placement, durability, and wash performance to ensure branding remains clean and consistent over time.